Dr.Krishnakumar B

- Dr.Krishnakumar B

- Senior Principal Scientist

- krishna@niist.res.in

- 0471-2515291

- +919447386706

Dr. Krishnakumar B is a native of Mayyanad in Kollam district, Kerala. He did his B.Sc. and M.Sc. in zoology under the University of Kerala. Subsequently, in 1994 he joined CSIR-RRL Trivandrum as a research scholar. He pursued his research on Microbiology, and obtained his Ph.D. degree in 2000 from the University of Kerala. In October 2000, he was awarded with the prestigious STA postdoctoral research fellowship from the govt. of Japan, and he joined National Institute for Environmental Studies, Tsukuba, Japan. Until 2003, he continued his postdoctoral studies in Japan. In March 2003, he joined CSIR-RRL as a fellow scientist, and later, on October 2014, he joined RRL as a permanent scientist, and presently working as Senior principal scientist & Professor in the CSIR academy.

His major research activities include-

- Biological waste (Solid & Liquid) treatment systems

- Environment clean-up solutions

- Waste-valorisation systems

- Microbial ecology of engineered biological systems

- Environmental impact of emerging micro-pollutants

- Molecular microbial analysis, etc.

Ongoing Research Programmes

Bioprocesses for waste (solid & liquid) treatment & resource recovery

The treatment, and safe disposal of organic wastes (solid and liquid) is crucial for the sustainable development for any society. Most of the wastes are resource rich, that can be tapped through proper scientific interventions. In our approach we use special microbial system in engineered biological systems to recover resources like bioenergy, reuse quality water, organic manure, natural fibre, etc. from waste materials. The deep understanding in aerobic/anaerobic/anoxic microbial processes, development of special microbial systems, application of the knowledge base for developing innovative approaches for treating various wastes, application of the microbial system and translating the developments into technologies, and further scaling up for field application are the major focus of our research.

The treatment, and safe disposal of organic wastes (solid and liquid) is crucial for the sustainable development for any society. Most of the wastes are resource rich, that can be tapped through proper scientific interventions. In our approach we use special microbial system in engineered biological systems to recover resources like bioenergy, reuse quality water, organic manure, natural fibre, etc. from waste materials. The deep understanding in aerobic/anaerobic/anoxic microbial processes, development of special microbial systems, application of the knowledge base for developing innovative approaches for treating various wastes, application of the microbial system and translating the developments into technologies, and further scaling up for field application are the major focus of our research.

Ongoing major project:

1. Scale up and field installation of compact food waste bioenergy systems.

Ongoing major project: Installation of food waste bioenergy system for Thiruvananthapuram airport:

Design, installation, commissioning, and operation of a food waste bioenergy system for Thiruvananthapuram International airport. The project was funded by Airport Authority of India (2018-2020).

The process is working on dry digestion principle (Solid content >15%, and Volatile solid loading >5 Kg/Cub M) in plug flow type bioreactor operating in parallel. That can manage and handle normal issues with anaerobic digesters. The major highlight of the process are-

- No fresh water addition into the digester.

- No fresh water addition into the digester.

- No fresh water addition into the digester.

- The Volatile solid reduction >90%, so the slurry is highly stable without any odour.

- The slurry can be used as organic manure.

CSIR NIIST installed the system in Dec 2019 and were operating the unit for over one year (till June 2020). The total biogas produced (~80 Cub meter) is recovered as Power (~1.5 Kwh per cub meter), that was used for local lighting and operation of the plant.

Small capacity (50 Kg/day) of similar systems are most ideal for canteens, marriage halls, schools, apartments, housing colonies, etc. These units can treat any food waste (both cooked and uncooked including egg shell, lemon, onion peel, etc. These compact digesters unit are portable, and occupies small space for installation.

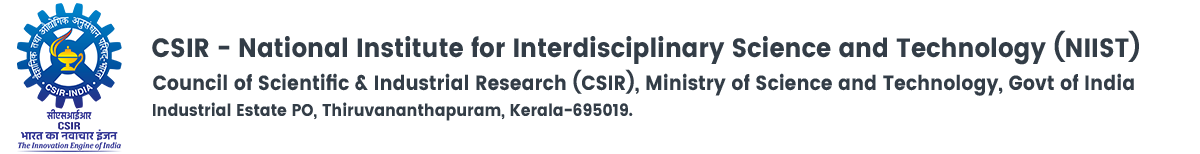

2. Modular onsite wastewater treatment system (NOWA):

Development Project funded by CSIR (2018-2020)

The treatment and safe disposal of high strength waste water from small establishments like hotels, restaurants, catering units, community halls, etc. in cities is a big challenge. Similarly, the wastewater from industries like bakery, agro based MSMEs are also challenging.

The existing treatment system in the market like the MBBR have major limitations like, its space requirement, cost (installation and operational) and their poor efficiency to treat organic rich (COD> 1000 mg/L) discharges.

NOWA is a novel treatment system developed for onsite treatment of high strength wastewater. This is specially tuned for recovering reuse quality water and bioenergy from the wastewater. NOWA is a modular (pre-fabricated) unit, and its installation and operational cost are less compared with existing treatment systems.

.jpg)

The newly developed treatment system is already installed in one of the bakeries for treating high strength wastewater. Also installations are progressing at hotels.

The technology is ready for licensing.

NOWA installed at an industrial site

3. Surveillance of perchlorate (Rocket fuel):

Our study during 2012-17, under CSIR funded 12th Five-year plant project flagged Perchlorate as an emerging endocrine disrupting water contaminant in India for first time. We reported massive ground water contamination (>50,000 ug/L against US EPA guidance level of 15 ug/L) of perchlorate (rocket fuel) at Keezhmad and Edathala Panchayats of Ernakulam dist. The contamination was observed around the ISRO-APEP (Ammonium perchlorate experimental plant) plant, extended up to 2 km.

Subsequent intervention of Kerala State health dept. has revealed a higher incidence of hypothyroidism among people in Kulakkad colony, who were exposed to perchlorate through drinking contaminated well water.

The counter measures suggested by us helped the recovery of most of affected people in 3 months, and prevented large number of people from getting affected.

Closed public wells in Kulakkad colony due to perchlorate contamination

We have also observed severe contamination (~4500 ug/L) of perchlorate at Sivakasi (TN) around the cracker industry cluster area.

We continue to monitor the progress of contamination in these regions.

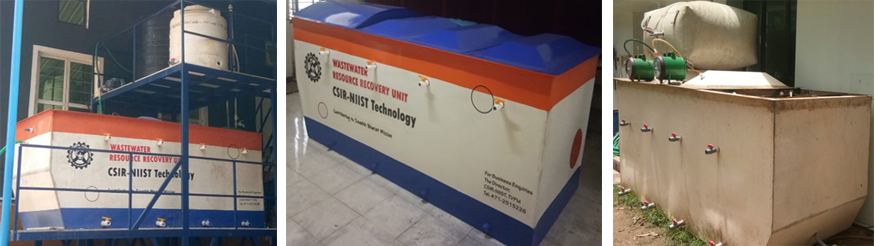

4. Bioremediation of Perchlorate:

To address the serious environmental, and public health challenges due to perchlorate, we have developed a bioprocess for decontaminating it. In this approach, we developed a bacterial system expressing key enzymes that reduces perchlorate completely into non-toxic chloride and oxygen.

The microbial system was translated into a bioprocess, and it was successfully tested for treating perchlorate containing water/discharges.

The developed process is patent protected: WO2017/125943 Al;

We have done pilot scale demonstration of the process. This can be applied for treating wash water from Rocket propellant plants, brines from perchlorate production plants and ground water contaminated with perchlorate. The technology is ready for licensing.

Novel ex-situ remediation process for perchlorate (rocket fuel):

We have found that massive perchlorate handling sites like space R&D units have soil contamination of perchlorate. Rainwater can easily wash this perchlorate down to ground water. Therefore, frequent monitoring and remediation (if needed) of the soil is highly important.

Recent, we have developed a novel ex-situ remediation process for treating perchlorate contaminated soil. This was demonstrated up to 0.75 T soil. In this approach the contaminated soil is flushed with water, and the contaminated wash water is regenerated (for washing next soil lot) in a bioreactor. The entire remediation can be completed in few hours. The technology is ready for licensing.

TECHNOLOGY & PROCESS

- AIR SANITIZER; Stand-alone air disinfection system for controlling aerosol mediated transmission of diseases. The technology licensed to two companies.

- NOWA (NIIST Onsite wastewater treatment system); A modular, onsite wastewater treatment cum resource recovery system for organic rich wastewater. The technology already licensed to two companies. Field units treating 10 KLD, Patent filed.

- Integrated-bio-physical process for treating perchlorate contaminated water. Patent published. TRL 8, Process demonstrated up to pilot scale.

- An ex-situ remediation process for soil contaminated with perchlorate. TRL 8. Process demonstrated up to pilot scale.

- A fermentative process for the production of Violacein, a high value bio-active compound. US, EU, & BR patented process. TRL 7.

Education

- M.Sc. Zoology; 1992 (University of Kerala, FMNC college, Kollam)

- B.Ed. Natural science; 1993 (University of Kerala)

- Ph.D. Microbiology; 2000 (University of Kerala, CSIR-RRL, Trivandrum)

Thesis title: Bacterial desulphurization of hydrogen sulphide

Research experience

- November 2004 to date; scientist in the Environmental technology division, CSIR-NIIST, Thiruvananthapuram.

- March 2003-November 2004; Fellow scientist, Environmental technology division, CSIR-Regional Research Laboratory, Thiruvananthapuram.

- October 2000-March 2003; Postdoctoral research fellow, National Institute for Environmental Studies, Tsukuba, Japan (Research heads; Prof. Y. Inamori & Prof. M. Mizuochi & N. Nishimura)

- March 1994-October 2000; CSIR-Research fellow (JRF, SRF & ESRF) CSIR-Regional Research laboratory, Trivandrum.