Technologies/Know-how

![]() Technology Brochure of Division

Technology Brochure of Division

TECHNOLOGIES ON OFFER

- Agriculture waste-based biodegradable products (plates, cups, cutleries etc.,)

- Vegan Leather from agro residues and wastes for replacement of chemicals from synthetic leather.

- Technology package for integrated processing of spices for essential oil, oleoresin and active ingredients extraction.

- Dehumidified dryers (RADD) for shelf life enhancement of agri/food products.

- Natural sweeteners in the form of free-flowing powders and syrups.

- Technology package for RTC based food products from various agro produces.

- Dietary fiber from coconut by-products and coconut processing industries.

- Micro encapsulated products for vegetable oil/Ayurvedic industries.

- Technology for value addition of spend materials from food/nutraceutical/Ayurvedic industries.

Technology

- CSIR NIIST has developed and commercialized agro-residues based biodegradable plates and cutleries.

- It is easily biodegradable, has good water retention and heat resistant capacities, Good strength, stiffness and microwave friendly.

Main features

- It can be used as an alternative to single use plastics like plates, cups, spoon, fork, take away units etc.

- This can be used by anyone, who care for environment.

- It will degrade within 30 days and leaves no harm.

Achievements

- Technology has been transferred to 14 companies so far and 4 companies have started their commercial production.

- Products are available in markets as well as in online.

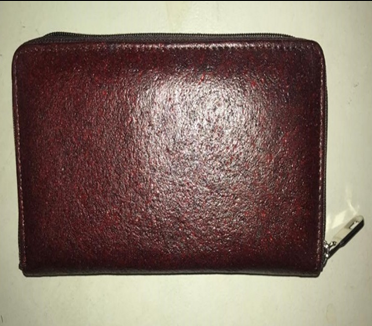

VEGAN LEATHER FROM AGRO RESIDUES AND WASTES FOR REPLACEMENT OF CHEMICALS FROM SYNTHETIC LEATHER

Technology

- CSIR NIIST has developed and commercialized agro-residues based vegan leathers and products as a replacement of synthetic leather.

- It is easily biodegradable, has good water retention and heat resistant capacities, Good strength, stiffness and microwave friendly.

Main features

- It can be used as an alternative to synthetic leather.

- This can be used by anyone, who care for environment.

- It possess mechanical properties as equivalent to available synthetic leather in the market.

- Involves less chemicals and less utilities like water and energy.

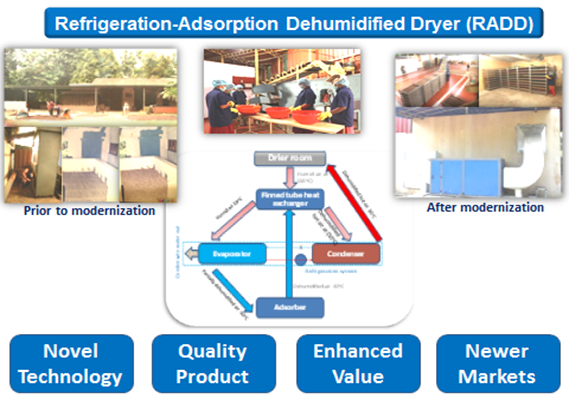

DEHUMIDIFIED DRIER FOR FOOD / AGRO PRODUCES

Technology

- CSIR NIIST has developed and commercialized dehumidification dryer for dehydration of food & agro products.

- CSIR NIIST has developed and commercialized dehumidification dryer for dehydration of food & agro products.

- Most suitable for the processing of heat sensitive exotic spices, fruits & vegetables.

Main features

- Ideal for setting up of unit with 1-2 tons per day capacity.

- Since the air is recycled back into the drier room rather than venting it out to the atmosphere, energy is conserved.

- There was a 60% reduction in total process time compared to conventional mode of for drying for agro crops.

Market potential

Scope for value addition, shelf life enhancement and export market for a variety of dehydrated produces from fruits & vegetables, spices & herbs, onion, mushroom, flowers and leaves with superior quality.

FRESH GINGER PROCESSING TECHNOLOGY

Technology

CSIR – NIIST Thiruvananthapuram has developed and commercialized ginger processing technology for producing value-added products such as ginger oil, dry ginger powder, etc. The institute has set up processing units (5-7 TPD capacity) in the north east and has transferred technology to many industries. CSIR NIIST provides know-how, and technical assistance in sourcing the machinery, engineering consultancy, training the operating staff, assist in erection & commissioning, etc.

Main features

- Fresh spice processing has the advantage of high-quality products with fresh aroma and better yield

- Mechanical drying of spices operations offer processing during rainy seasons

- Mechanical drying of spices operations offer processing during rainy seasons

- The process is green and no usage of toxic chemicals

Market potential

Very high value addition to spices with export potential in food and healthcare sector for specific produces such as organic ginger, ginger flavour/ extract and ginger powder.

NATURAL SWEETENERS – PROCESS DEVELOPED & NEW INITIATIVES

Background

- CSIR-NIIST has developed a wide range of natural sweeteners from plantation crops.

- Products are available in the form of solid blocks, semi-solid, powder and syrup form.

- Developed technology is energy efficient, involves natural clarifying agents, and without any additives/preservatives.

Achievements

- Developed free flowing Jaggery powders from Cane and Neera.

- Energy efficient and optimized use of clarified agent.

- Decentralized production, thereby empowers rural employment

- Spice enriched fortified syrups developed

Developed process for free flowing jaggery powder

- Agriculture waste-based biodegradable products (plates, cups, cutleries etc.,)

- Vegan Leather from agro residues and wastes for replacement of chemicals from synthetic leather.

- Technology package for integrated processing of spices for essential oil, oleoresin and active ingredients extraction.

- Dehumidified dryers (RADD) for shelf life enhancement of agri/food products.

- Natural sweeteners in the form of free-flowing powders and syrups.

- Technology package for RTC based food products from various agro produces.

- Dietery fiber from coconut by-products and coconut processing industries.

- Micro encapsulated products for vegetable oil/Ayurvedic industries.

- Technology for value addition of spend materials from food/nutraceutical/Ayurvedic industries.

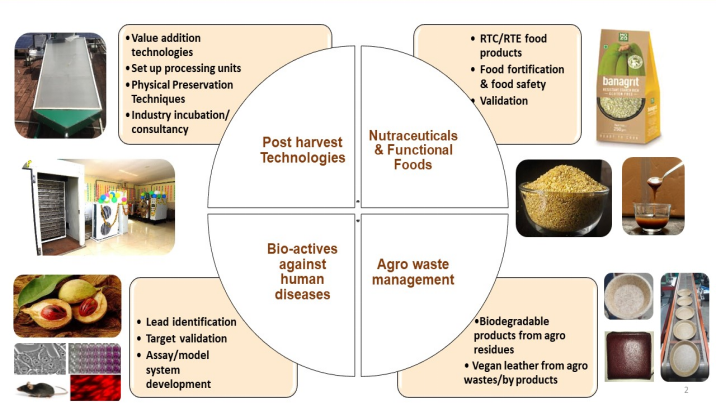

- Design/engineering consultancy, erection, and commissioning of industrial plants for agro-products.

- Establishment of industrial plants for agro-waste management for the development of biodegradable cutleries and vegan leather.

- Research activities pertaining to post-harvest management of agro products.

- Development of scientifically validated nutraceutical products in RTE/RTC forms.

- Food safety and consumer health - acrylamide studies, food toxicology etc.,

- Pharmacological evaluation of bio-actives for lifestyle related disorders

- Skill development short term courses and training programmes

- Technology transfer/Technology licensing

- Testing and analytical services

Achievements

-

Recipient of CSIR Shield for Process Technology 2004 for “Swing Technology”

-

Recipient of NRDC National Technology Award 2003

Highlights

- R&D, Industry interface programmes (sponsored & consultancy) for product and process development, technology up-gradation and scientific validation of health benefits.

- Red palm olein (RPO) based functional food products (functional vegetable oil & soft gel) for vitamin A deficiency.

- Pharmacological evolution of bioactive compounds from plants for metabolic disorder and Cancer.

- Bio-Processing of botanicals for active ingredient extraction through industrially important enzymes from native microbes.

- Bio-fertilizers and bio-pesticides from microbes with special emphasis on endophytic organisms.

- Development of mitochondrial antioxidant micronutrients through conjugation of triphenyl phosphonium with natural products.

- Dietary fibre from agri/food processing spent materials as metabolic enhancers.

- Acrylamide in foods and its mitigation strategies.

- Non-dairy beverages and delivery systems for nutritional and bioactive components.

- Source identification and validation of vegetarian proteins for geriatric health care applications.

- Value added products from traditional grains and underutilised fruits and vegetables.

- Biochemical, cellular and molecular level validation studies of specific treatment regimens employed in Ayurveda

Research facilities

- GC-MS with positive & negative ionisation with direct probe.

- Gas chromatograph (2)

- High Pressure Liquid Chromatograph (3)(preparative & analytical with photodiode array detector)

- Differential Scanning Colorimeter

- Supercritical Phase Equilibrium Analyser

- High Performance Thin Layer Chromatograph

- UV visible

- Solvent extraction units

- Wet extraction systems

- Size reduction equipments

- Presses (Screw presses/hydraulic presses)

- Dryers (cross flow & vacuum)

- Rotary drum vacuum filter

- General food processing systems

- Supercritical fluid extraction unit (2 lit.Thar, USA)

- 6” Molecular distillation (Pope, USA)

- 6” wiped film evaporator (Pope, USA)

- 6” wiped film cum fractional distillation system (Pope, USA)

- Neutralizer cum bleacher (25 kg Armfield, UK)

- Deodourizer (25 kg, Armfield, UK)

- Scrapped surface Heat Exchanger (Margarine marker) (10 kg/hr, Armfield, UK)

- Hydrogenation unit (25 kg, Armfield, UK)

- Membrane technology plant (10/kg / hr-RO, UF, nano, Micro filtration modules with ceramic membrane, PCI, UK)

- 50 kg Crystallizer

- Spray dryer (10 kg/hr, Niro, Denmark)

- Liquid-liquid extraction / separation system

- Continuous 3 phase centrifuge (200 kg/ hr, West falia)

- Freeze dryer (10 kg/hr )